An engineering handbook is a seven chapter text that covers the basic concept principles and applications of dc and speed motors and servo systems.

Servo motor control system pdf.

After providing the terminology symbols and systems of units this book goes on dealing with the basic theory motor comparison and basic speed.

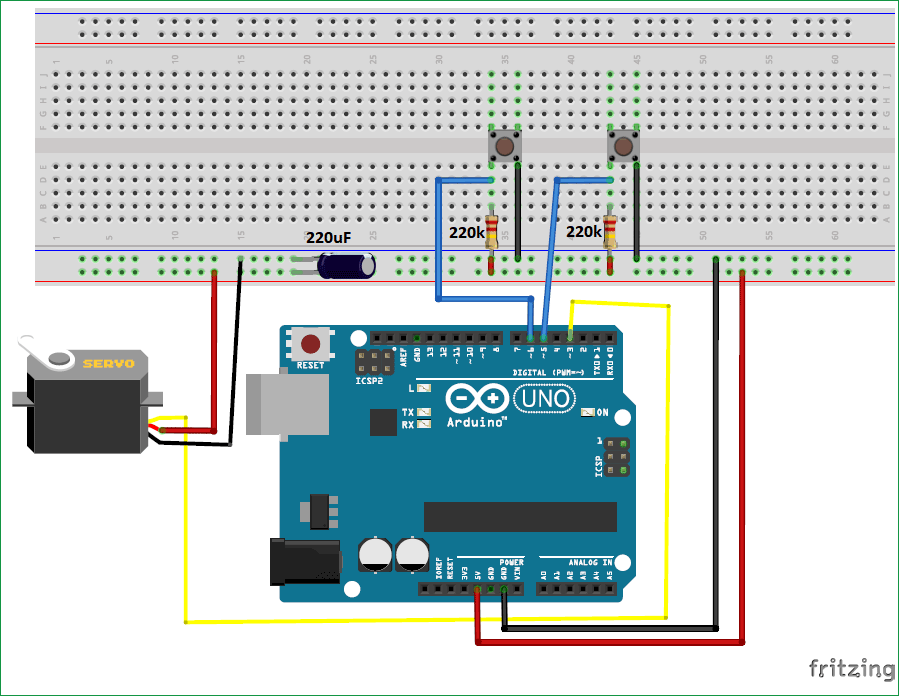

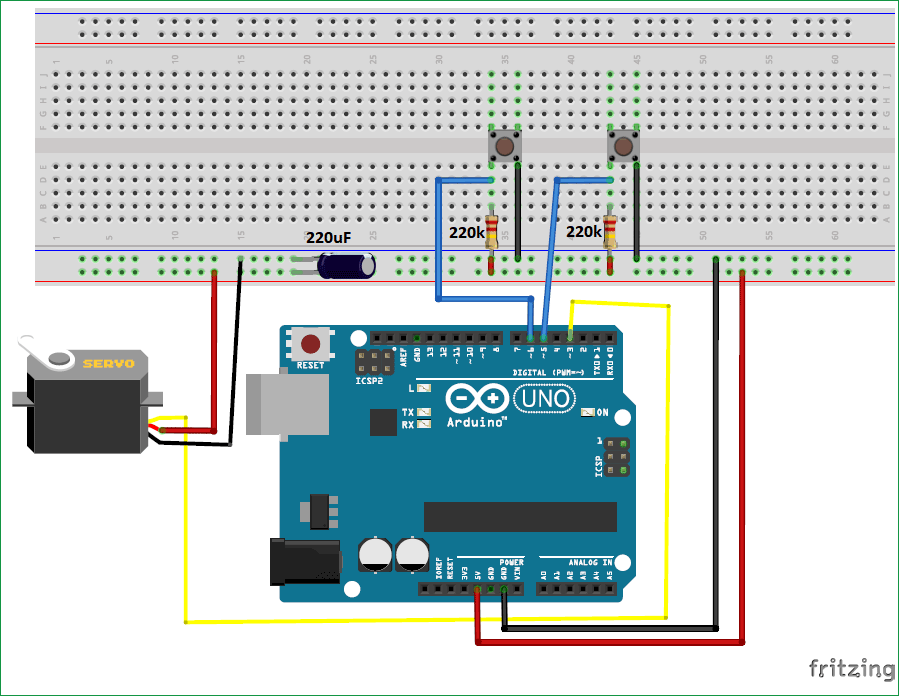

A dc servo motor is used as an actuator to drive a load.

They provide an off the shelf solution for most of the r c and robotic hobbyist s needs.

A servo motor is a linear or rotary actuator that provides fast precision position control for closed loop position control applications.

Dc motors speed controls servo systems.

This assembly may in turn form part of another servomechanism.

Servo motor basics and controll ciruits diagram pdf.

The servo system vary the controlled amount such as position speed or torque according to the set target value command value to precisely control the machine operation.

The details of controlling the direction and speed of the dc motor wirelessly are.

The servomotor includes the motor that drives the load and a position detection component such as an encoder.

Design a control system analyze the transient response fine tune the.

Servo motors have a high speed response due to low inertia and are designed with small diameter and long rotor length.

A servo system primarily consists of three basic components a controlled device a output sensor a feedback system.

Dc motors are constructed using rare earth permanent magnets which have high residual flux density and high.

Servo system configuration example encoder servomotor table.

A potentiometer provides a simple analog signal to indicate position while an encoder provides position and usually speed feedback which by the use of a pid controller allow more precise control of position.

Without hobby servos hereafter referred to only as servos you would have to.

A servomotor is a specific type of motor that is combined with a rotary encoder or a potentiometer to form a servomechanism.

Hobby servos eliminate the need to custom design a control system for each application.

This is an automatic closed loop control.

It is usually a dc motor of low power rating.

Dc servo motors have a high ratio of starting torque to inertia and therefore they have a faster dynamic response.

Dc servo motor.